Wire feed

Diameter

Motorized finger rotation

Vertical pitch

Horizontal pitch

Cutter

Retracting mandrel

Vertical mandrel

Axes

Sizes

Configurations

Machine

Wire range (mm)

n/a - n/a

RX 3

Material and coiling ratio

A wide working range to meet every need and request

<Maximum efficiency in the production of right and left springs>

<AxeName>

<AxeName>

<7 axes and the latest generation multi-axes numerical control will give you control on every micron>

Strengths

<Introducing SPC: The Advanced System for Precise Spring Measurements>

<The MX Spring machine incorporates a cutting-edge feature that utilizes a video camera to capture accurate measurements of the spring's length and diameter. This statistical process control (SPC) feature ensures that every spring produced meets the desired specifications, resulting in consistent and reliable performance. With this technology, you can trust that your MX Springs will meet your exact requirements every time.>

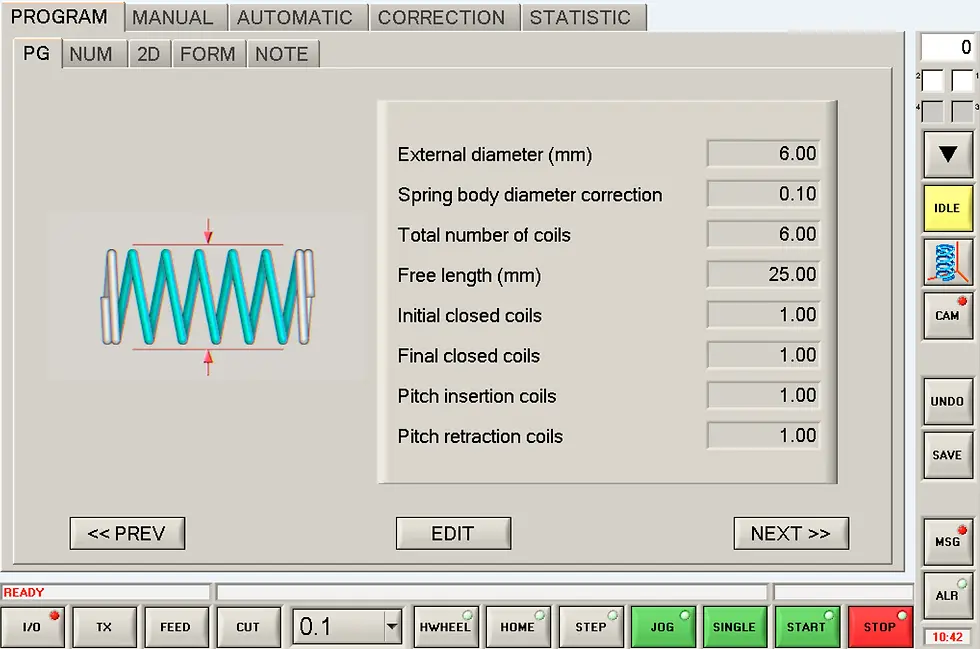

<Featuring an industrial PC and large color touchscreen display, the machine offers easy accessibility to all operators, allowing a effortless digital modification of any machinery settings>

<Hundreds of customers around the world trust our advanced and reliable software and use it daily to optimize their spring production process>

<Maximizing spring production efficiency with our high-quality P models pay-offs>

<Pay-offs are a critical component of spring manufacturing. Our precision pay-offs are designed to maximize efficiency and accuracy in the production process. They enable consistent tension and control during the unwinding of wire from spools, ensuring a uniform feed rate and preventing wire breakage. With our precision pay-offs, you can achieve the high-quality results you need for your spring production.>

Wire feed

Thanks to digitally adjustable pressure, it ensures precise and consistent wire feed, essential for the production of high-quality springs.

Diameter

Each winding finger is driven by 4 independently interpolated axes. Easy and intuitive tuning thanks to advanced features for the tangential and radial movement of the winding fingers.

Horizontal pitch

It is tasked with creating the pitch between the spring coils through a movement parallel to the axis of the spring itself.

Vertical pitch

It is tasked with creating the gap between the coils of the spring through a movement perpendicular to the axis of the spring itself.

Vertical mandrel

It ensures ease of machine setup thanks to the precise vertical adjustment of the mandrel.

Retracting mandrel

The rapid retraction of the mandrel ensures high productivity in every situation. Great ease of machine setup thanks to the precise mandrel horizontal adjustment.

Cutter

The ability to use three types of cutting:

Vertical cutting, rotary cutting, and torsion cutting.

Extremely fast change of cutting type thanks to ergonomic and innovative solutions.

Motorized finger rotation

Exclusive patent that allows both winding finger to rotate during the spring forming process to optimize the tool/wire contact point based on the winding ratio and desired pre-load.

<7 axes and the latest generation multi-axes numerical control will give you control on every micron>

<The ultimate solution to revolutionize your spring sorting process>

<With their innovative brushless motorized system, our chutes offer 100% of sorting reliability, providing you with unparalleled speed, performance, and controllable precision. Our advanced C Series Chutes come in a range of sizes (C0, C1, C2, C3), making them a versatile and essential accessory for any spring production line. Upgrade your sorting process with the C Series Chutes and experience a new level of efficiency and accuracy.>

Have even more flexibility and productivity with optional accessories

<title>

<title>

<title>

<Seeking additional information? Our official Simplex Rapid representative is ready to assist.>

© 2023 by Simplex Rapid · All Rights Reserved · P.IVA 00700220155 · Privacy policy