0.05

Minimum Wire Diameter (mm)

0.2

Maximum wire diameter (mm)

7.5

Maximum external spring diameter (mm)

90

Maximum wire feed speed (m/min)

5

Electric Power (kW)

640

Depth (mm)

1150

Width (mm)

2000

Height (mm)

760

Net weight (kg)

7

Number of axes

Wire feed

Diameter

Motorized finger rotation

Vertical pitch

Horizontal pitch

Cutter

Retracting mandrel

Vertical mandrel

Axes

7

Number of Servo Motors

Sizes

Configurations

Machine

Wire range (mm)

0.05 - 0.2

FX 3

0.1 - 0.8

FX 5

0.15 - 1.1

FX 10

0.25 - 1.5

FX 15

0.4 - 3

FX 30

Material and coiling ratio

A wide working range to meet every need and request

<Maximum efficiency in the production of right and left springs>

<AxeName>

<AxeName>

<7 axes and the latest generation multi-axes numerical control will give you control on every micron>

Strengths

quick and intuitive setup, to easily set even the most complex springs

3 steps

faster than the previous generation, ideal for long run production

+50%

unparalleled mechanical precision thanks to the use of direct kinematics

0 play

Introducing SPC: The Advanced System for Precise Spring Measurements

The use of state-of-the-art digital cameras and advanced algorithms allows us to detect and measure the main geometric parameters of the produced springs. The values of free length and outer diameter are read with extreme precision even at high production speeds, and the process is kept within the set tolerances by automatically applying the calculated correction.

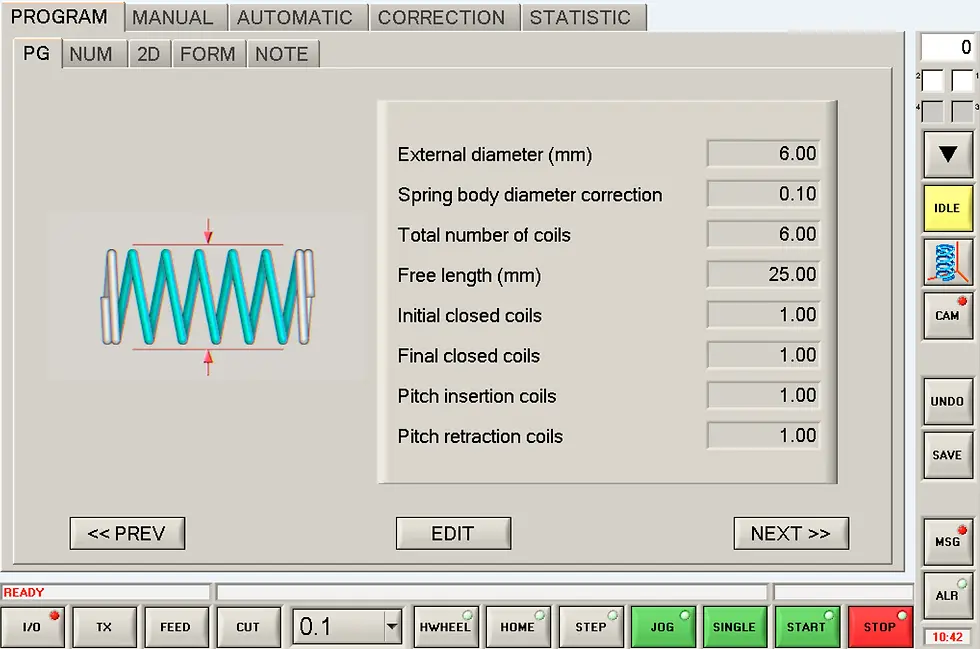

A user-friendly software with a large touchscreen display optimizes production and provides easy access to programming parameters for human-machine interaction (HMI).

Hundreds of customers around the world trust our advanced and reliable software and use it daily to optimize their spring production process

Maximizing spring production efficiency with our high-quality P models pay-offs

Pay-offs are a crucial component in spring production. Our pay-offs are designed to maximize efficiency and accuracy in the production process while ensuring maximum safety. They provide constant tension and control during coil unwinding, ensuring a uniform speed without wire deformation. With our technologically advanced pay-offs, you can achieve the high-quality results you need for your spring production.

Wire feed

Thanks to digitally adjustable pressure, it ensures precise and consistent wire feed, essential for the production of high-quality springs.

Diameter

Precise control of the spring diameter through an independent axis.

Horizontal pitch

It is tasked with creating the pitch between the spring coils through a movement parallel to the axis of the spring itself.

Vertical pitch

It is tasked with creating the gap between the coils of the spring through a movement perpendicular to the axis of the spring itself.

Vertical mandrel

It ensures ease of machine setup thanks to the precise vertical adjustment of the mandrel.

Retracting mandrel

The rapid retraction of the mandrel ensures high productivity in every situation. Great ease of machine setup thanks to the precise mandrel horizontal adjustment.

Cutter

The ability to use three types of cutting:

Vertical cutting, rotary cutting, and torsion cutting.

Extremely fast change of cutting type thanks to ergonomic and innovative solutions.

Motorized finger rotation

Exclusive patent that allows both winding finger to rotate during the spring forming process to optimize the tool/wire contact point based on the winding ratio and desired pre-load.

7 axes and the latest generation multi-axis numerical control ensure precision to the micron

The ultimate solution to revolutionize your spring sorting process

With their innovative brushless motorized system, our chutes offer 100% of sorting reliability, providing you with unparalleled speed, performance, and controllable precision. Our advanced C model chutes come in a range of sizes (C0, C1, C2, C3), making them a versatile and essential accessory for any spring production line. Upgrade your sorting process with the C model chutes and experience a new level of efficiency and accuracy.

Have even more flexibility and productivity with optional accessories

<title>

<title>

<title>

<Seeking additional information? Our official Simplex Rapid representative is ready to assist.>

© 2023 by Simplex Rapid · All Rights Reserved · P.IVA 00700220155 · Privacy policy